Finishing: Côtes de Genève

The final finish is applied to my bridges... But unfortunately, my work isn't done yet. I'll get back to why in a moment.

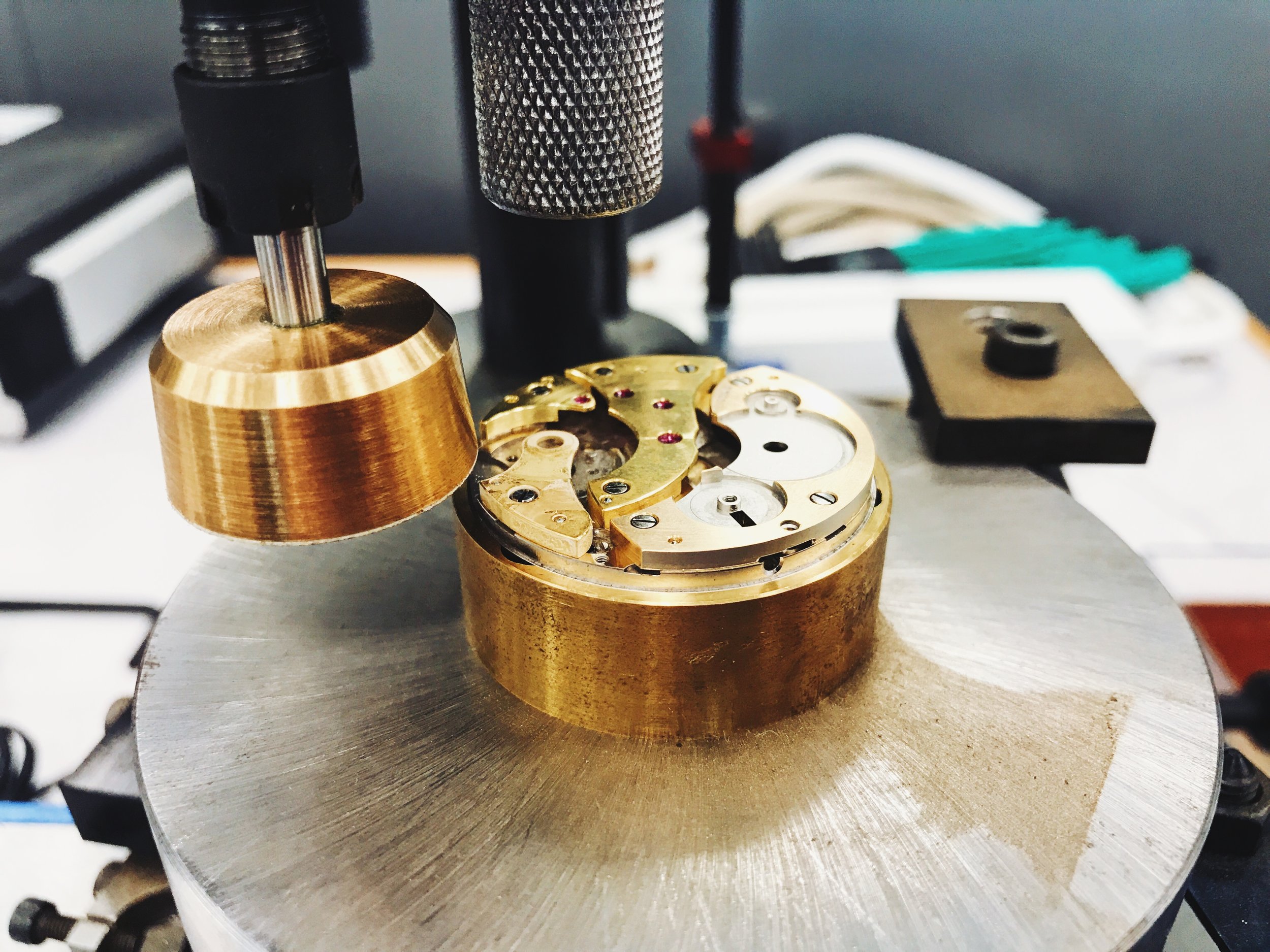

Côtes de Genève (Geneva striping) is a traditional finish that is applied to upper bridges and components (some automatic rotors, for example) that are visible at the top of the movement. It's widely regarded as the most classic of high-end watch finishes, and we're lucky to have access to a machine that will allow us to apply it to our school watches.

The finish itself is similar to perlage in that it uses rotating abrasives to scratch the bridges in pleasing patterns. The machine that applies the finish, however, is a different story. It's a relatively simple device, though it is perfectly built and extremely precise. A mandrel holds an abrasive disc, which is very slightly angled and lowered onto the bridges, which are passed back and forth on a carriage.

An adjustable vertical stop allows the operator to very carefully lower the disc further and further onto the bridges to get evenly-deep stripes. The carriage indexes forward by equal amounts each time the thumb lever is pressed, allowing the stripes to be evenly spaced.

The machine makes it easy to keep all the stripes on the same level, but that also means that all of the bridges have to be on the same level to begin with. Mine were slightly higher in the center than the outside, forcing me to stripe the middle more than the edges... And thus removing more material there than anywhere else.

The stripes came out beautifully, but my bevels... My precious bevels... They're mostly gone. The bevels around the center wheel jewel have been reduced to a mere deburring. Worse, the bevels are now uneven, which is unaccaptable. I'll have to recut them, though now I'll have to be more delicate than ever to avoid marring the striping!

The jewel countersinks are also pretty much gone. I'll have to pop the jewels out to rechamfer the holes.

You can see the texture especially well in this image. The rotating abrasive leaves these arcs, which are truncated by the next stripe behind it. The slight angle on the carrier is necessary to achieve the sharp demarcation between stripes.

It will be a real challenge to rebevel the bridges without marring the surface finish, but we've been training all year for handling high-end watches, so it should be possible! I don't have much time left, so I'm glad that I had plenty of practice earlier.

Watchmaking student at the Lititz Watch Technicum, formerly a radio and TV newswriter in Chicago.