Lathe: Shellac Chucks

Lathes work great for cutting round workpieces, but what about irregular shapes?

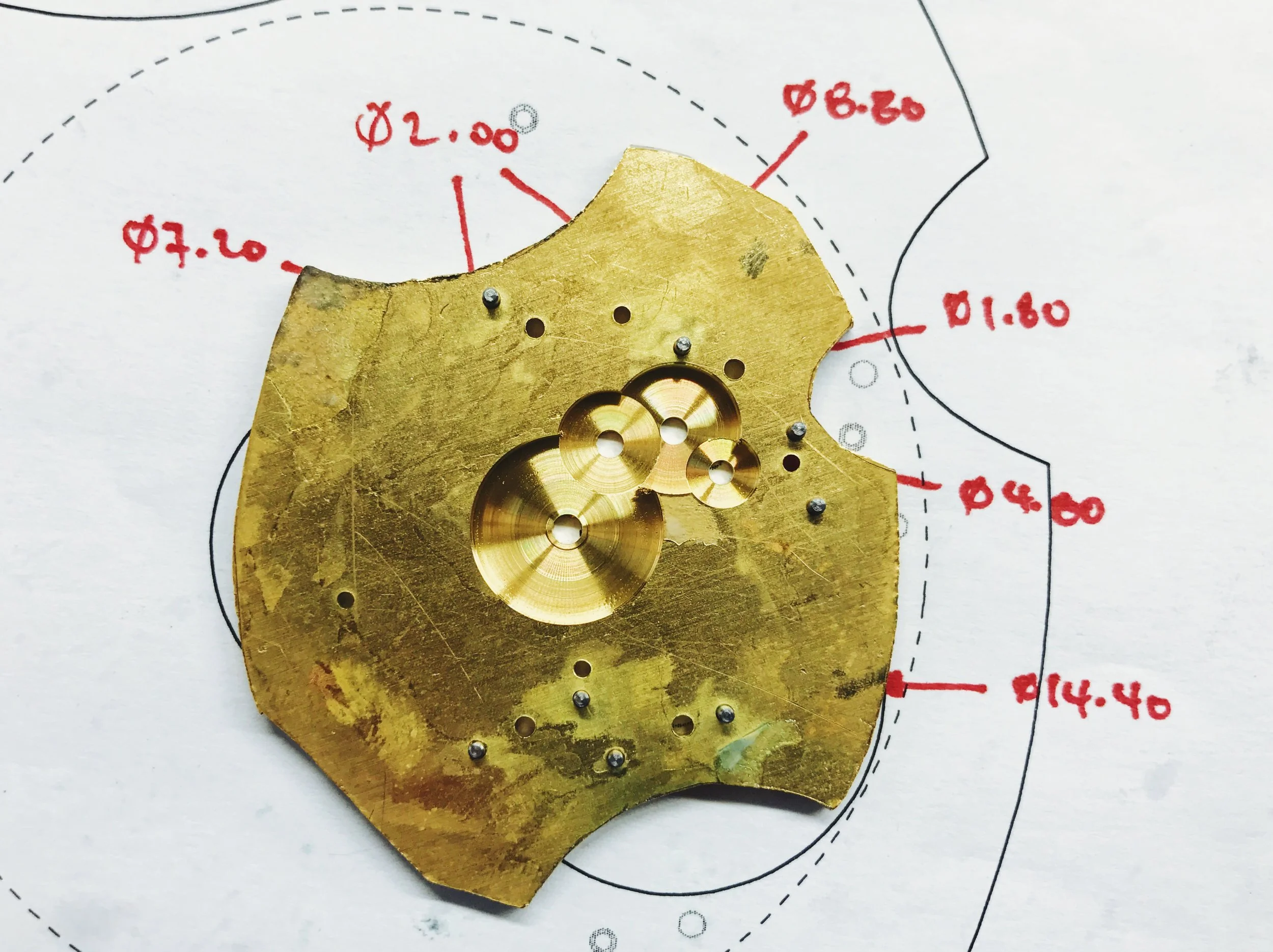

So far, we've only used collets to clamp our cylindrical workpieces. Today we're using shellac (or glue) chucks to hold flat brass instead.

Aside from having to tilt the lathe on its side to heat the shellac properly, it's not so different than a normal cutting operation. The irregular corners of my brass made a frightening *thwack thwack thwack* during machining, but it ultimately became a nice tool.

In the photo above, you can see the workpiece as its in the midst of turning from a rough square into a circle. The red Sharpie is a basic guideline that i made for myself, but as with anything we make, the final diameter can only be determined with an actual measuring device.

I'll be revisiting this technique later, to repair a part of my clock. I improperly drilled one of the escape wheel pivots, and had to "plug" the plate with some round brass stock to center the pivot properly.

The problem is that our round brass and flat brass have different metallic compositions, and the color difference is easily visible—so now I'll have to turn a piece of the flat stock to a cylinder to replace the plug that I've already made.

Watchmaking student at the Lititz Watch Technicum, formerly a radio and TV newswriter in Chicago.