Pigeon Clock: Restoration

After a lot (and I mean a lot) of scrubbing, the pigeon clock is ticking and back together in time for SAWTA 3!

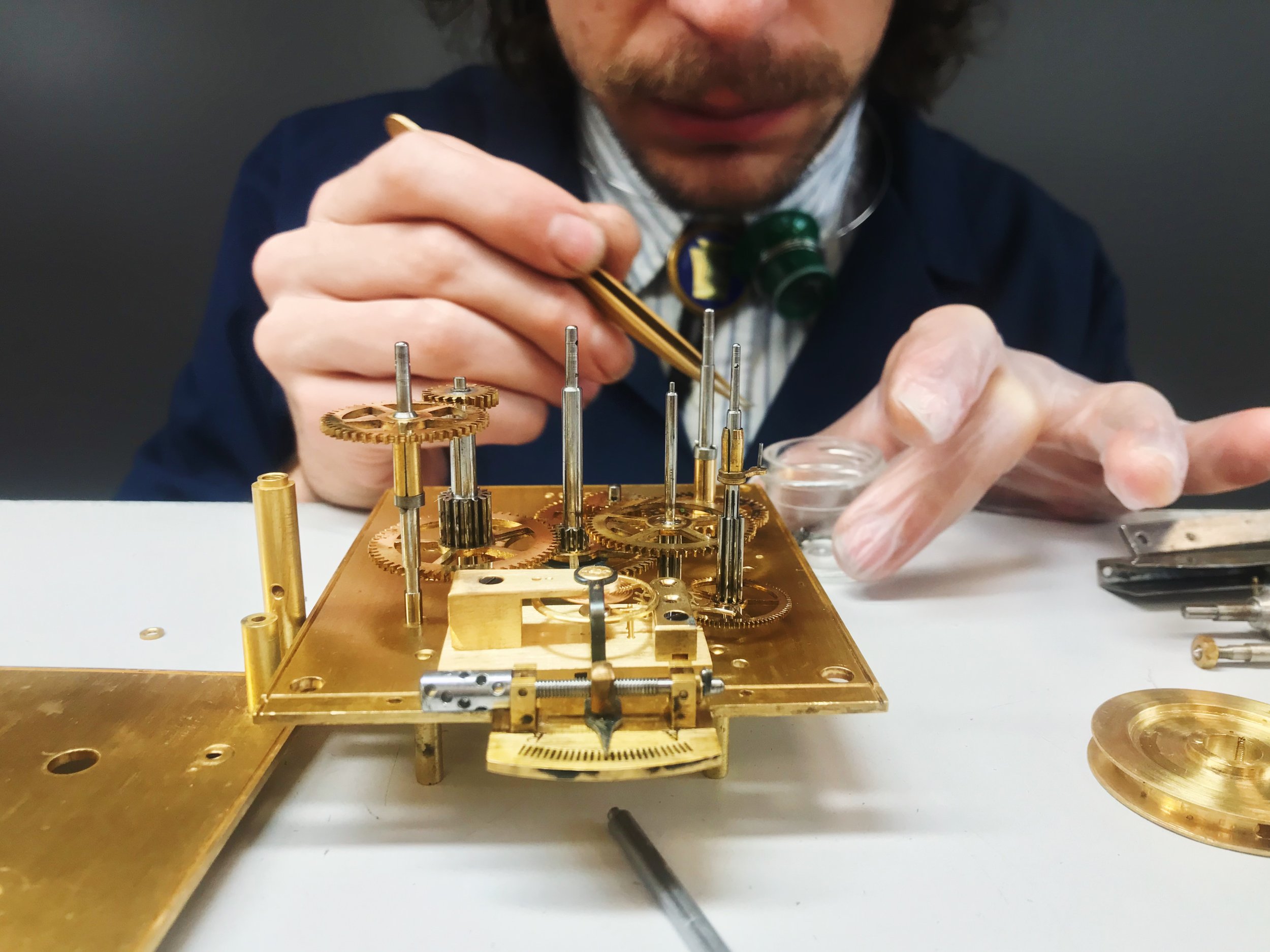

The clock and printing mechanisms comprise two different modules, which were cleaned and serviced separately. The insides of the clock were actually in pretty good shape, since the movement is sealed on the sides by steel walls (not installed in the above photo).

The clock uses a surprisingly beautiful 11-jewel platform escapement. Many similar escape wheel clocks use pin pallets, but this one is fully jeweled and extremely high quality.

The pallet fork is especially well made. The top is flat-polished, the sides are perfectly hand-beveled and the counterweight has even been properly poised! Just look at how those bevels form the guard pin.

I am extremely indebted to Justin (seen here assembling the clock module) for his help in getting this thing cleaned up—he works for a local clockmaker outside of school hours, and his experience with this kind of mechanism was invaluable.

Before (bottom) and after (top).

Cleaning the parts made a huge difference in aesthetics. An ammoniated cleaning solution, much scrubbing and a long bath in the ultrasonic tank removed 100 years of tarnish and grime from these wonderful components.

Between the clock and the printing components, it was a lot of parts to clean and relacquer.

The clock was especially well-made, with beautifully formed wheels and pinions, and polished wheel faces.

Properly cleaned, the components reveal themselves to be little works of art. The gorgeous chains serve to retract the platen during the printing process, and the steel lever system seen here exists only to punch a mark in the time log in case of tampering. Talk about overengineering!

It’s an enchanting little ball of clockwork when both mechanisms are assembled together. All that remains is to get the clock properly regulated and to rebuild the inking mechanism before it goes back in the case for the test!

A charming touch on the clock mainspring to end this article.

Watchmaking student at the Lititz Watch Technicum, formerly a radio and TV newswriter in Chicago.