Downsizing: Intro to Ladies' Movements

Our first movement, the 6497, is large by watchmaking standards. The ETA 7750 and Rolex 1575 are smaller, but still average-sized in the grand scheme of things. Our next challenge is small.

"Ladies'" watches (an unfortunate, but universal term in watchmaking) are significantly smaller than their "men's" equivalent, which means that their movements are similarly shrunk.

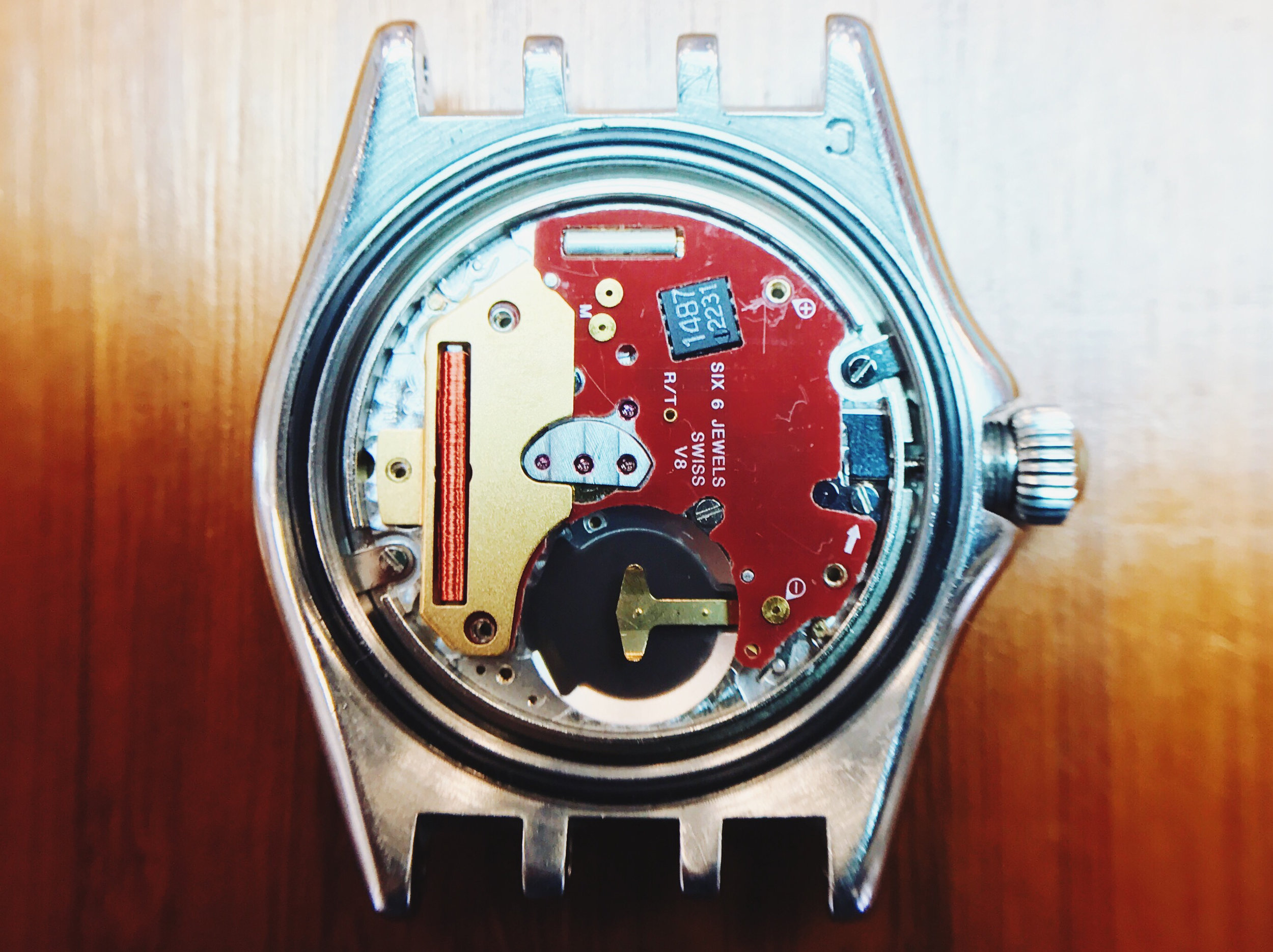

Many ladies' watches get around this shrink by simply using quartz movements, but they're also home to some of the watch world's tiniest mechanical movements, especially in vintage pieces.

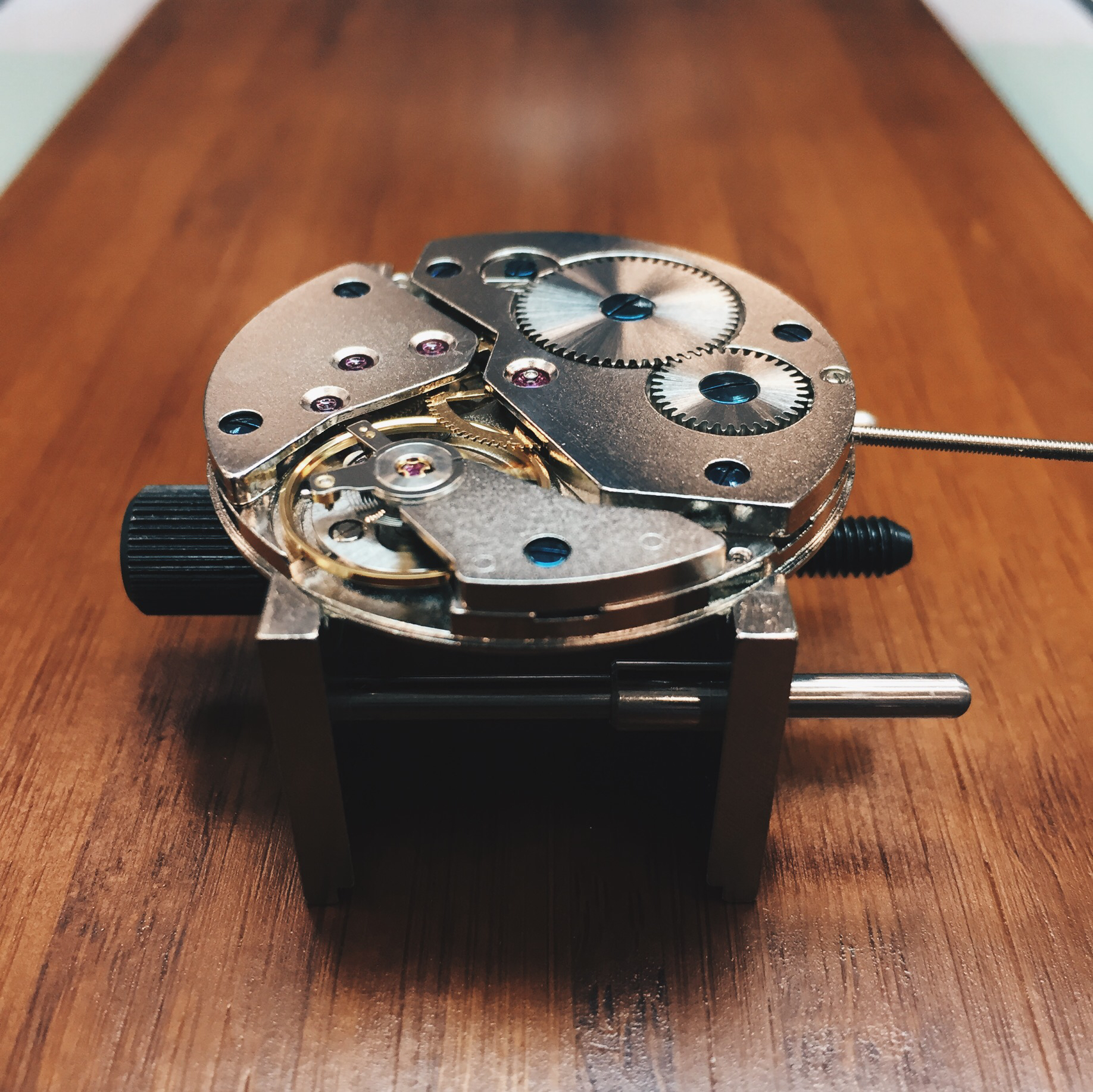

The FEF 6630 is a minuscule thing, but it's not even on the the small side, as ladies' movements go. Still, it's barely bigger than my thumbnail, and it's roughly the same size as just the balance wheel from the 6497. In fact, it's so small that we don't have a movement holder to clamp it!

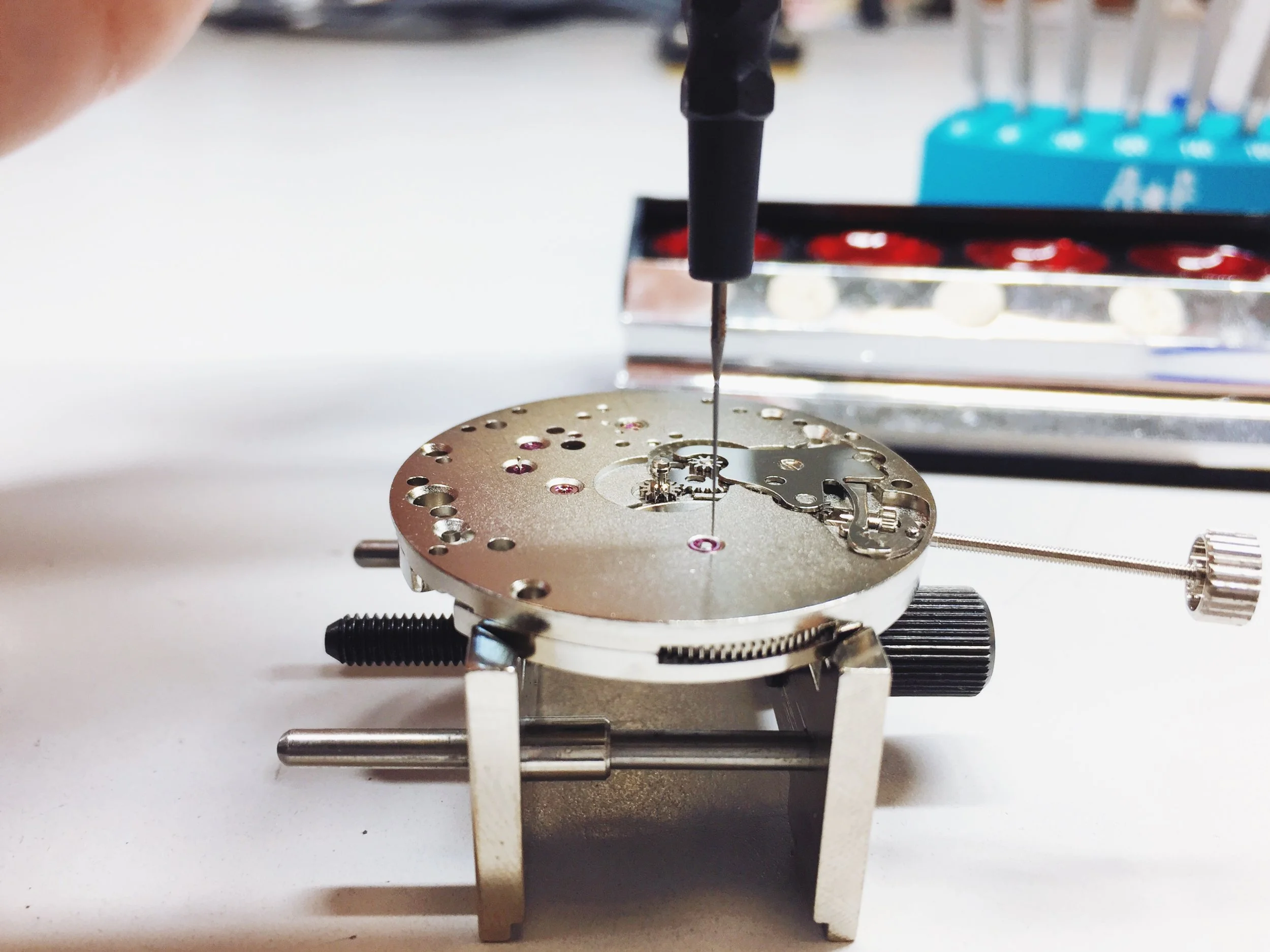

This was the challenge that welcomed us back from our week off for Thanksgiving. To make it even more daunting, we essentially had no spare parts (aside from some shock springs), so we can't break or lose anything. Deep breaths, now.

Luckily, aside from the size, it's not hard to service—and to be honest, the size stopped being an issue more quickly than I anticipated. The hairspring work seriously leveled up our tweezer skills, so dropping parts (or rocketing them across the room with too much pressure) was almost a non-issue.

The 6630 is a time-only watch, like the 6497, and most of the parts are in the same places and work the same way. The classic movement layout just works, and it's found in most watches when possible.

Oiling the jewels was a little bit tricky as well, since the targets are so small, but since they're large in comparison to the surrounding movement, it actually felt fairly easy. A little bit of psychological trickery perhaps, but whatever works. It would have been impossible a couple of months ago, but the constant practice has dramatically improved our motor control.

The real issue with oiling was actually the order of operations. Since the movement is so small, some of the jewels are obscured at full assembly, which means that we have to oil the jewel before the wheel is dropped into its pivot. This isn't the preferred way to do things, but it's acceptable when necessary.

We'll be working more with these movements as we go forward, but it's encouraging to be presented with a dramatic challenge like this and come out victorious!

Watchmaking student at the Lititz Watch Technicum, formerly a radio and TV newswriter in Chicago.