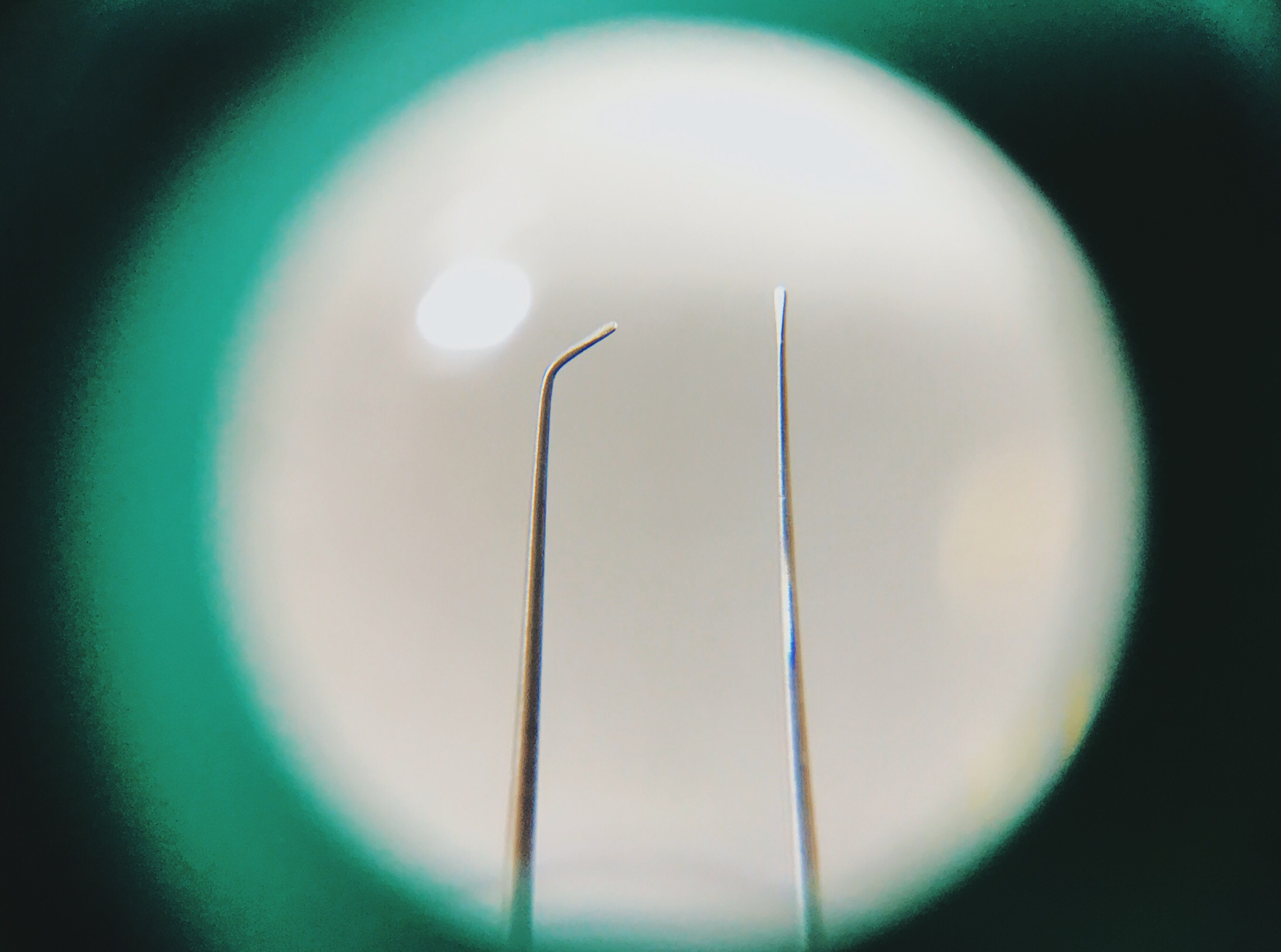

Tools: Tweezers

If the loupe is a watchmaker's eyes, tweezers are the hands.

Tweezers' utility should be fairly self-evident—you're not really able to pick up teeny-tiny watch parts with your bare hands. Some big pieces, sure, but most parts are far too small. Besides, you shouldn't be touching them with your hands anyway.

There are many rules to remember during watch service, but the first one is this: do not touch a clean watch component.

Do not touch a clean watch component!

Once a movement goes through the cleaning machine, it's a hands-off affair. The oils on your hands can actually etch marks into the metal if it's not cleaned, so even accidental touches are unacceptable. Luckily, if your tweezer skills are up to par, it won't be a problem.

Building up your tweezer dexterity isn't easy, but it's absolutely necessary to be a successful watchmaker. Too little pressure, and you're dropping tiny parts on the floor. Too much pressure, and you're launching them into orbit! When it comes to small, smooth, round pieces (like jewels), only the right touch will do.

We have a variety of tweezers, but the most commonly-used pair is made of brass. The soft metal is unlikely to scratch sensitive parts, but the tips dull easily. Other pairs are made of bronze, nickel and steel (stainless and high-carbon), and they all serve different purposes.

Don't make the mistake of thinking that these are the same as the tweezers that you use to pull splinters or pluck your eyebrows. The tips on a watchmaker's tweezers must be kept in near-perfect condition, or they simply won't work. Don't cheap out when it comes to these critical tools!

Watchmaking student at the Lititz Watch Technicum, formerly a radio and TV newswriter in Chicago.