First Graded Service

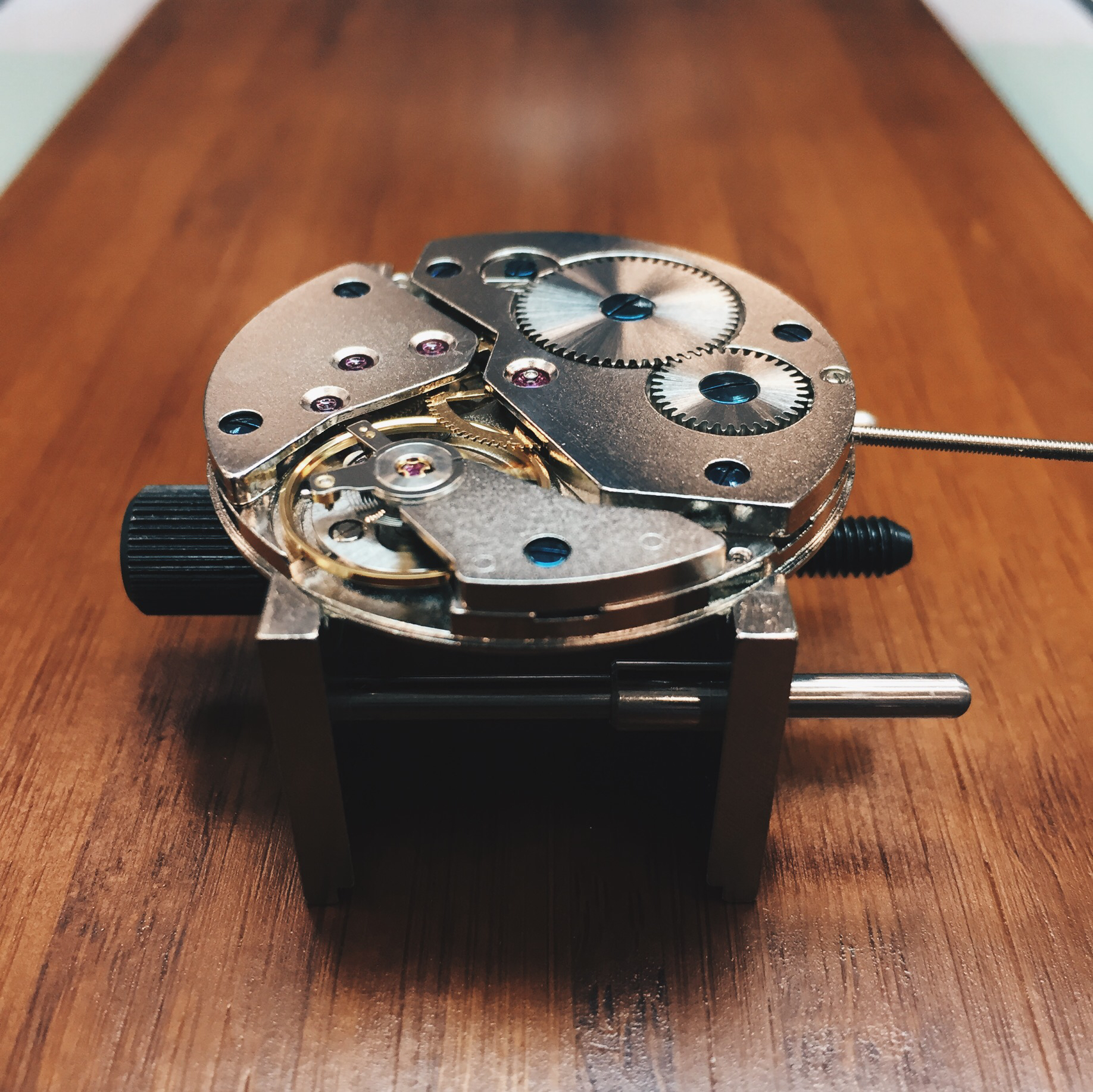

We've learned to take the 6497 apart, clean it, oil it and put it back together, so now it's time to test our skills.

This service will focus on four main points:

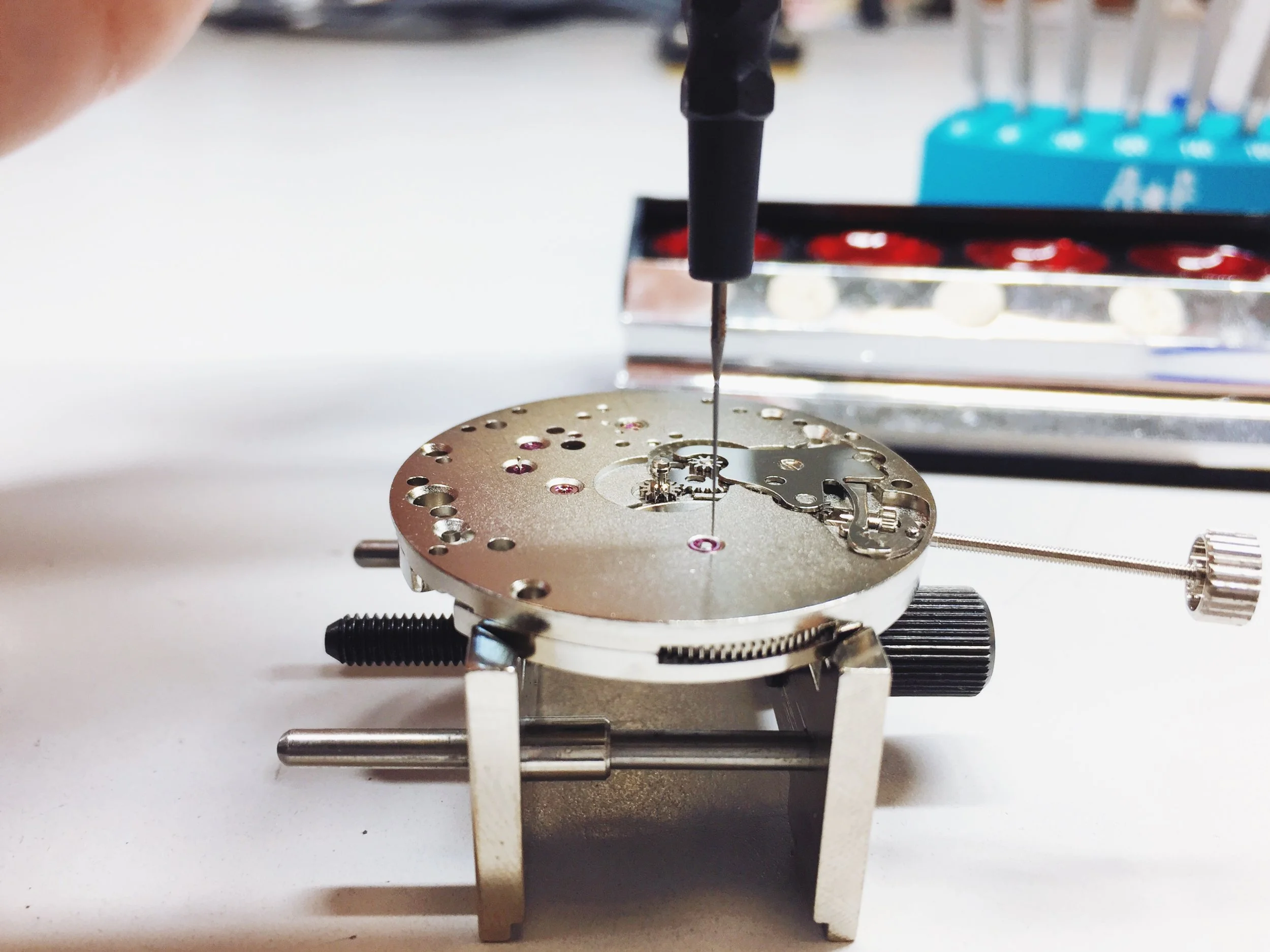

- Lubrication. All lubrication points must be adequately oiled or greased. Dry pivots fail.

- Cleanliness. No fingerprints on the clean movement, and no oil anywhere that it shouldn't be.

- Screw Torque. Our instructors frequently remind us that some of the most common reasons that students fail exams is because of loose screws and dry pivots. Tighten those screws!

- Endshakes. Remember that jewel that I shattered? That was during endshake adjustment—that is, the amount that a wheel (gear) can move up and down in its pivots. Those are measured in hundredths of a millimeter, but can have a huge effect on a movement if they're wrong.

Service takes a clear head and a steady hand. I've found that I have to take it easy on coffee during watchmaking days, since even a little hand shake can make oiling a mess!

The 6497 is the easiest movement to service that we'll face. The jewels are large and easy to oil, and it's a simple design. They'll only get more complicated as we go on.

Watchmaking student at the Lititz Watch Technicum, formerly a radio and TV newswriter in Chicago.