Quartz: Component Casualties

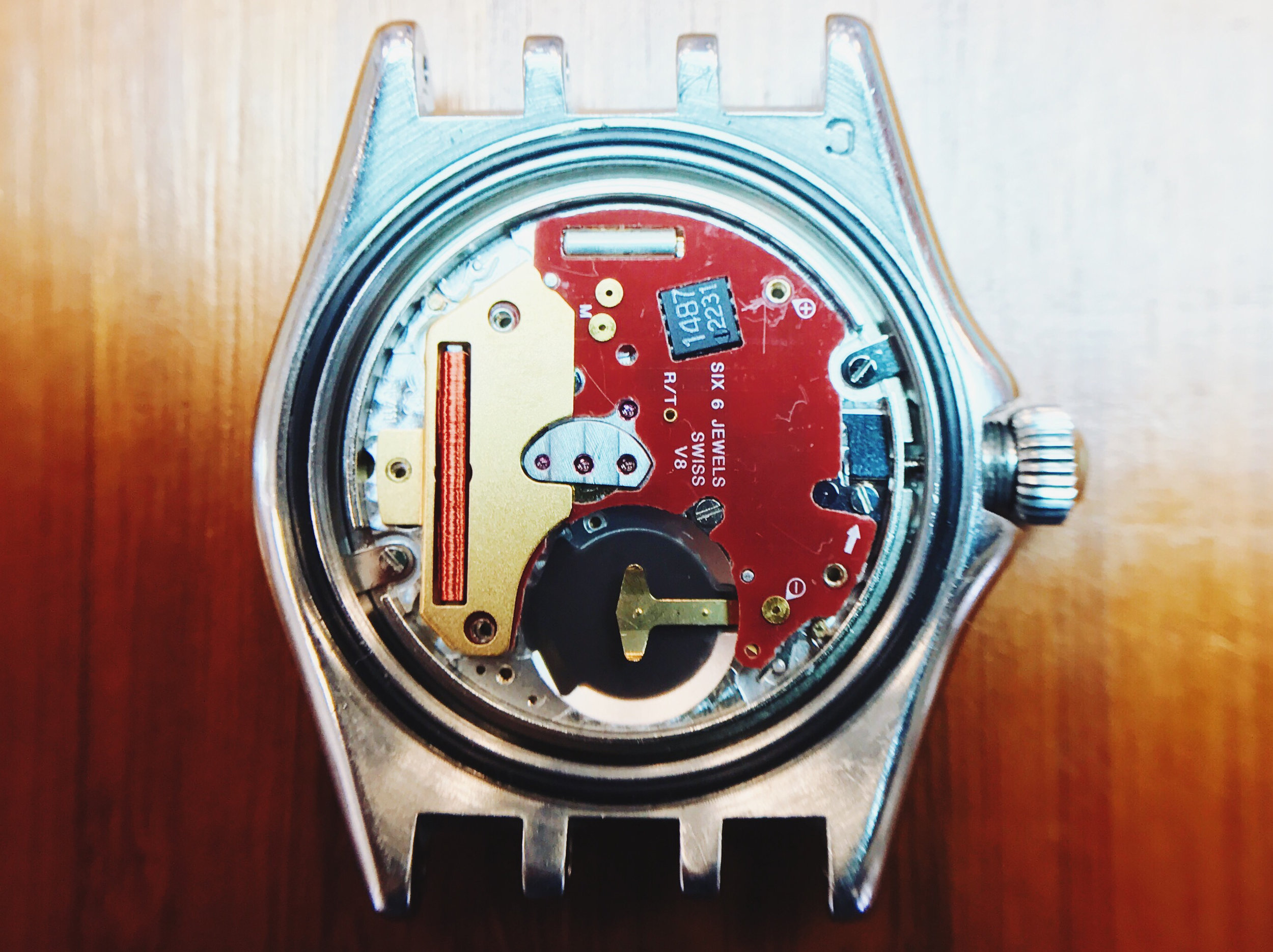

Our class did some serious damage to these coils.

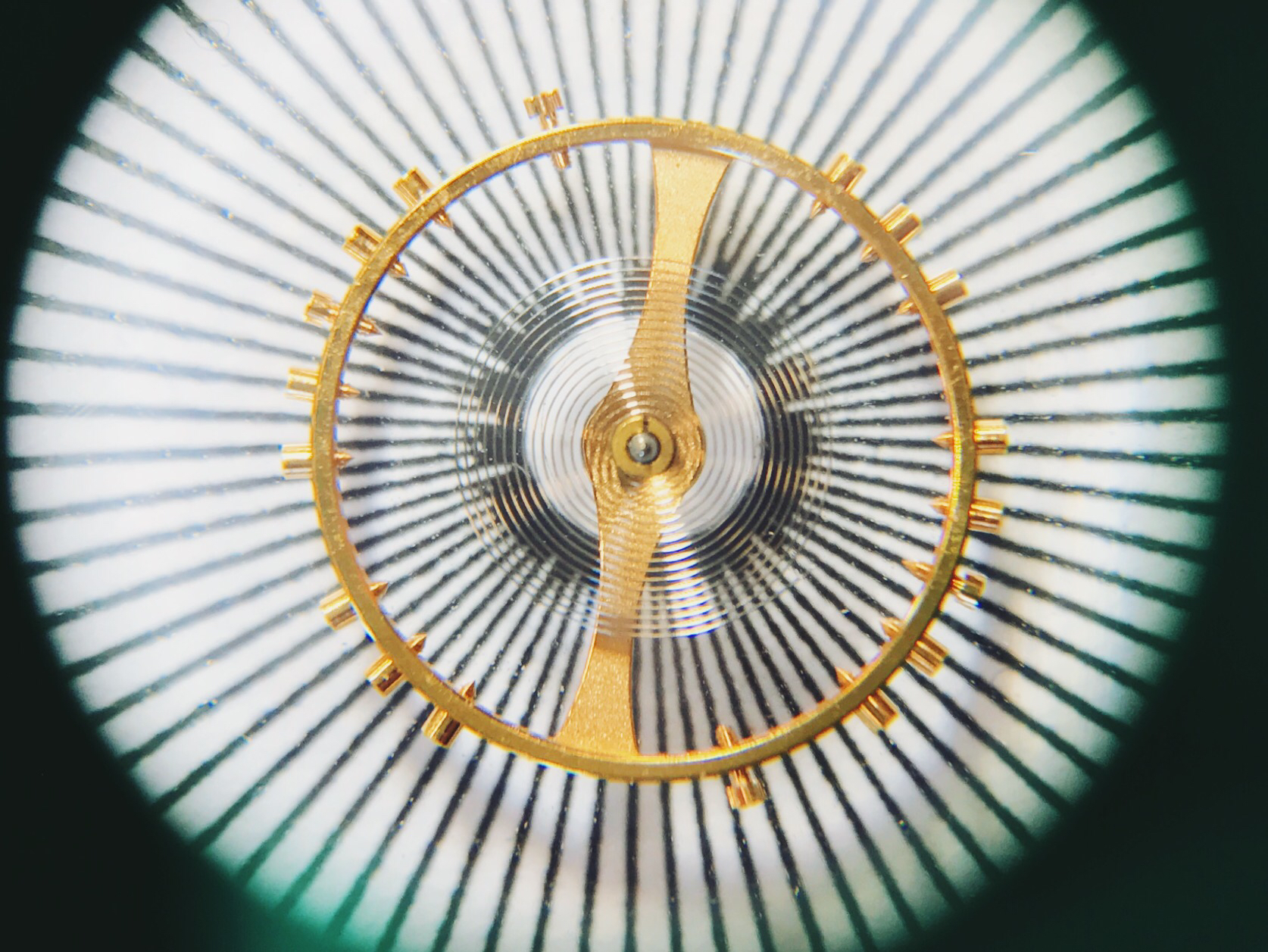

The coil is one of the most important parts of a quartz watch. A current runs through the wire, generating a magnetic field, and the coil focuses it on the stator. This creates the oscillating magnetic field that allows the permanent magnet rotor to spin, driving the motor.

The coiled wire has to be extremely long to generate the requisite magnetic field, so in order to fit it into a small watch movement, the wire must be commensurately thin. Extreme care is required when dealing with the coils, since a break in the wire will ruin it completely.

All of these coils suffered from broken wires, mostly at the most sensitive ends where they are soldered to their contact points. A disconnected wire will simply fail the motor completely.

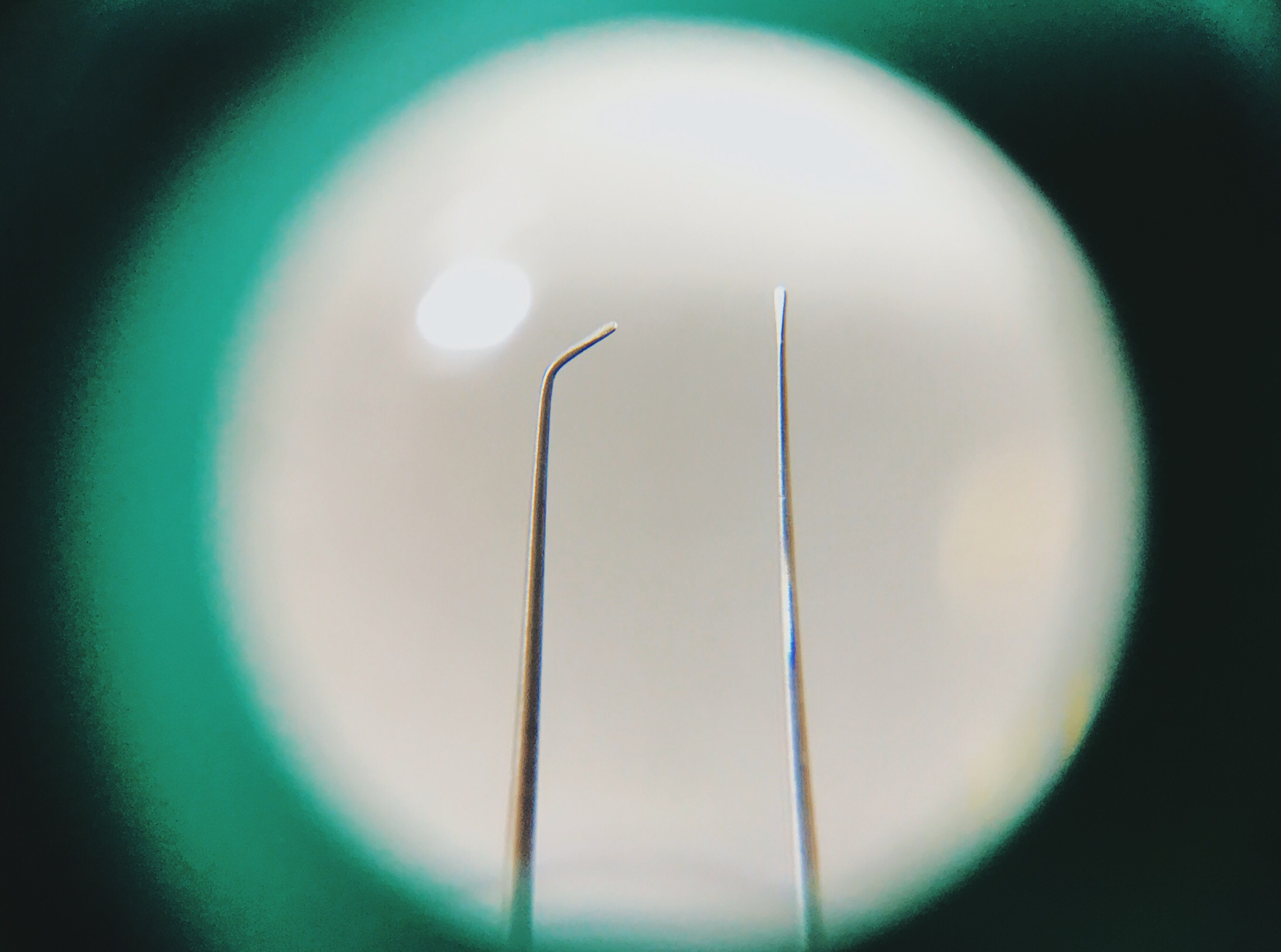

Luckily, there's a handy automotive tool that can repair this kind of break. Conductive paint is used on cars to repair broken "wires" in the defroster grid on rear windows, and it works just as well on a small scale with these coils. Rather than try to solder the wire back on (risking considerably more damage), a small oiler can simply paint them back in place.

Watchmaking student at the Lititz Watch Technicum, formerly a radio and TV newswriter in Chicago.