School Watch: Bridge Shaping

There are two ways to shape the school watch bridges: by hand or using the lathe.

All of the watches are following the same general design, and we have transparencies to glue to the tops of the bridges for guidelines. Regardless of the method used to form the bridges, the spacing between bridges should be equal—between 0.80 and 1.20 mm. The gap size matters less than keeping it equal between every bridge.

To shape the bridges by hand, you simply file them until they're fully-formed. Filing by hand is a true test of manual dexterity, since the design we're following contains numerous compound curves and sharp points. Not only do these portions of the bridges need to be sharp, but they have to be perfectly smooth and square as well.

The other option is to form the bridges on the lathe, which I did. Using the lathe is time consuming and requires a significant amount of setup, but when properly implemented, it will result in flawlessly shaped pieces.

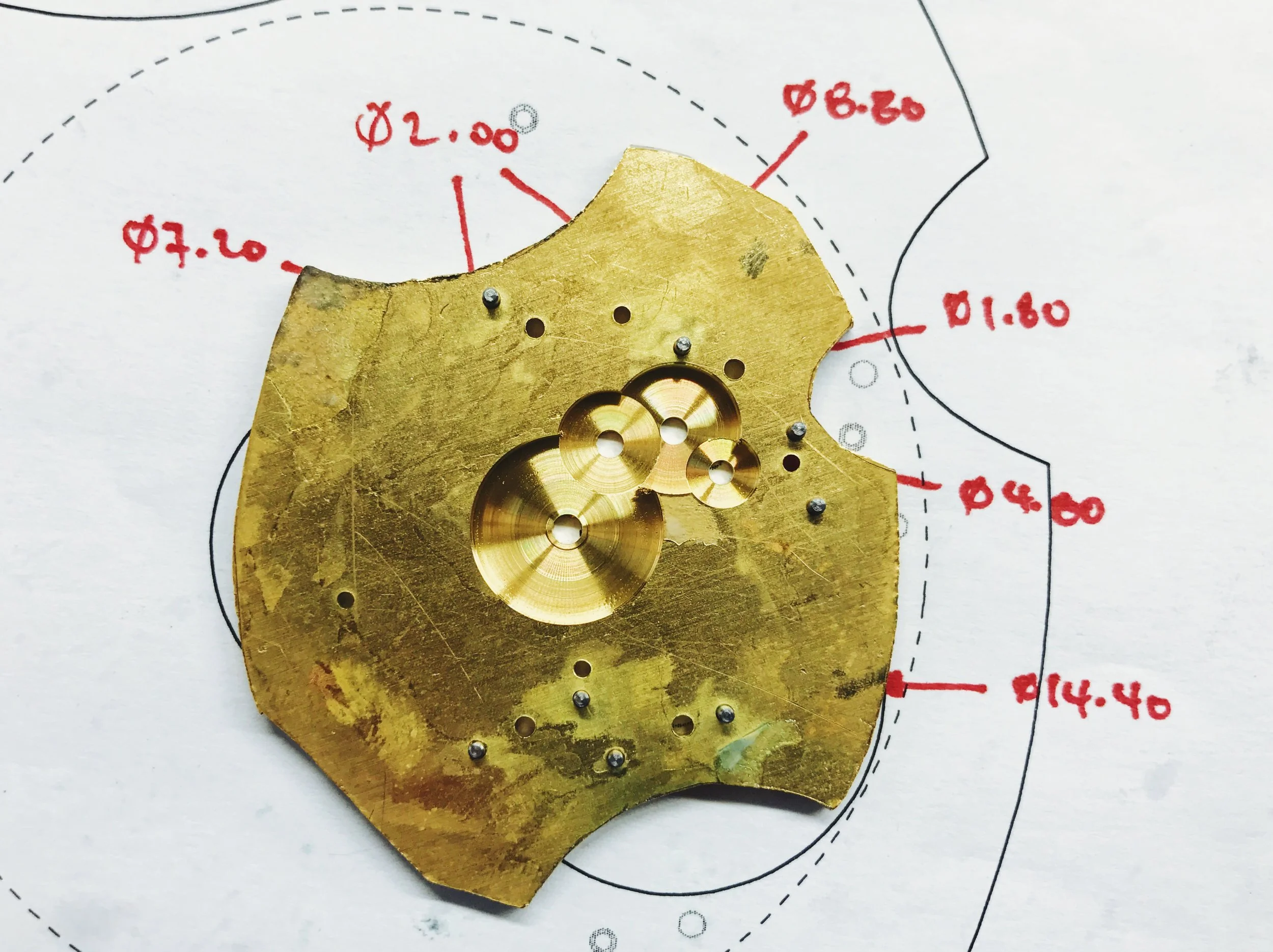

The curves of the bridge designs are all based on radii, some of which are centered on parts of the watch, and some which are... Well, not entire random, but definitely impossible to locate without help. A second set of transparencies has centering targets that will allow us to use the faceplate to define these curves.

To cut the bridges, just center on the target with the centering scope, and set the cutter in the boring position. Since most of the curves interfere with each other (or the jaws of the faceplate) the lathe can't make full rotations, and the headstock has to be rotated by hand.

Since this is a manual operation, the depth of cut has to be very small. Advance the cutter by a small amount, turn the curve, advance again, and continue until you reach the mainplate. That's it! Since there are at least a dozen curves to center on, this process can take a while. Of course, most of machining hinges on the setup—the operation itself is simply the execution of a proper procedure.

This took a while, but I'm satisfied with the results. After lapping the sides to apply a fine line finish, the next steps are to face off the bridges and start beveling. That's going to be the true test of hand work!

Watchmaking student at the Lititz Watch Technicum, formerly a radio and TV newswriter in Chicago.