Weirdo Project: Pigeon Racing Clock

Here's a bit of horological arcana: an early 20th century pigeon timer from Belgium that I'm restoring to use during our watchmaking exams.

I had no idea that pigeon racing was or is a thing, but apparently it continues to exist around the world as a pastime. These clocks are used to determine the winner of races, and are extremely neat little machines. Here's how they work:

- Pigeons are released from a set location at a set time, at which point the clock is started.

- As each pigeon arrives at the homing location/"finish line," an identifying band is taken from the bird's leg and placed into the clock.

- A crank is turned, locking the band into a numbered carousel and printing time-stamped a "receipt" for when it was stored.

- After all the birds have been logged, the box is opened and the rings are removed from the carousel in the order they came in, allowing proctors to determine the winners of the race.

The clock itself is encased in a heavy wooden box with a complex mechanical interlock system that eliminates tampering. The door at the top is where the rings are dropped in, the window looks down on the printing mechanism, and the hole on the side is for the crank.

Opened, you can see the carousel and the printing mechanism. The crank pulls the platen up and over the printing plate, which charges the barrel on the right. As the platen falls onto the lower track, it runs over the paper and is pulled back by the chains on the barrel. Pins on the barrel pull the paper off the printer and out through the right side of the clock.

This is a look inside the carousel. As the mechanism is activated, it will rotate to position 2, and there on to 20, at which point this clock runs out of spaces and locks the carousel until the clock is opened to be emptied.

Here's the printing mechanism by itself. The wheel on the far side indexes the carousel as the crank is turned, and operates the platen arms via a pin and linkage on the visible side.

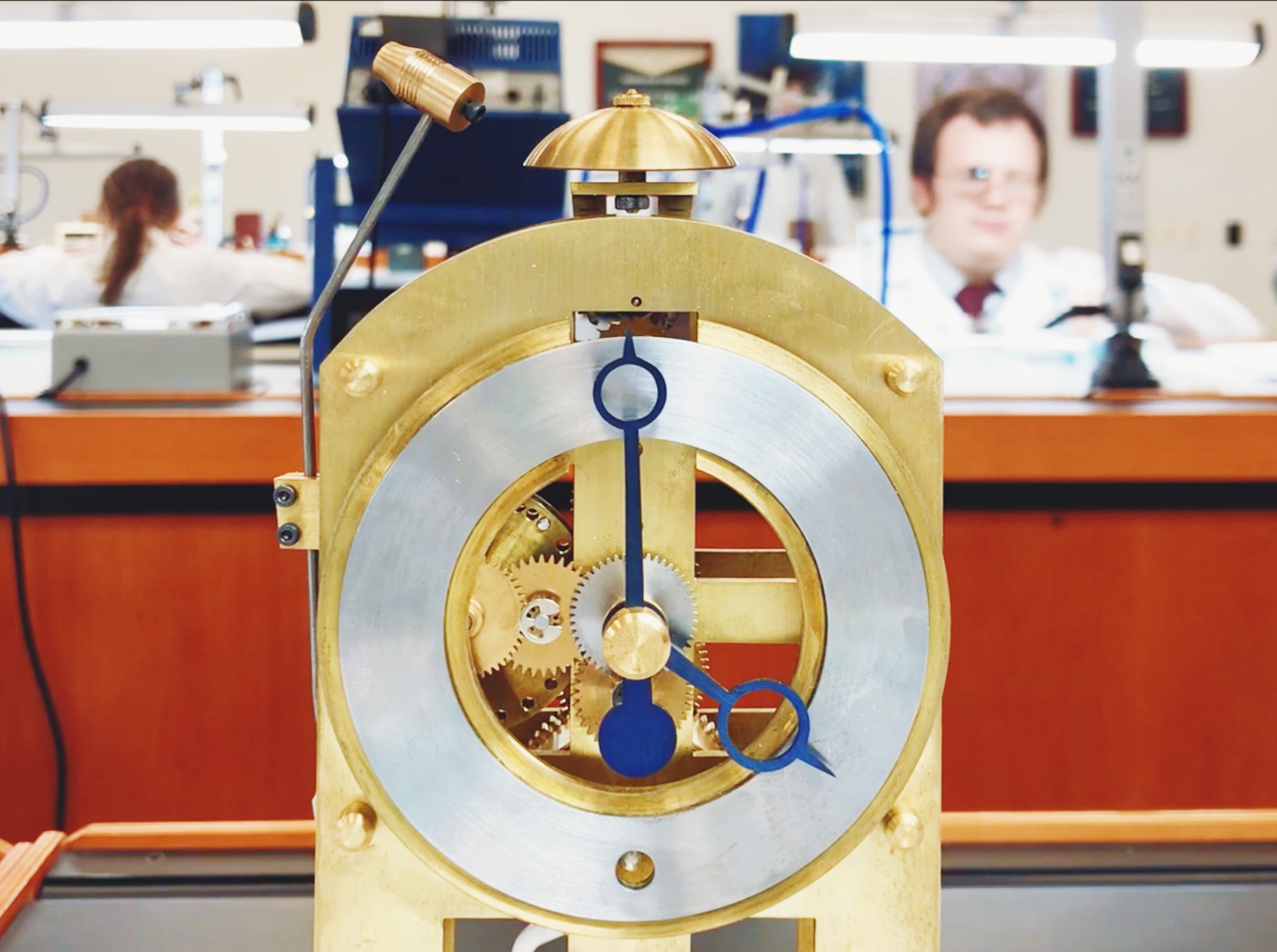

The timekeeping mechanism itself is a pretty standard-looking clock from the dial side. It uses a balance wheel, of course, and is enclosed on all sides to keep dust and ink out of the geartrain.

The unique feature of this clock is that the motion work (the elements that move the hands) is double-sided! This is the printing side of the clock, which carries hands that indicate the time on the printing plate. They're heavily buttressed and reinforced to withstand the printing process without bending the arbors.

The clock ticks and keeps good time, and the printing mechanism seems to work, so hopefully it'll just need a good cleaning to work perfectly again. I'm hoping to have it done in time for SAWTA 3; ideally, it will work as the timekeeper for the tests.

We use anonymized numbers when taking the tests instead of names, but just write them on paper, along with the time we turn in the exam. Instead, we could draw pigeon rings from a hat for our numbers, put them in the clock when we're finished and turn in the receipts as our official finishing time! Hopefully, my fellow students won't mind using my strange contraption during the stress of the test environment...

Watchmaking student at the Lititz Watch Technicum, formerly a radio and TV newswriter in Chicago.