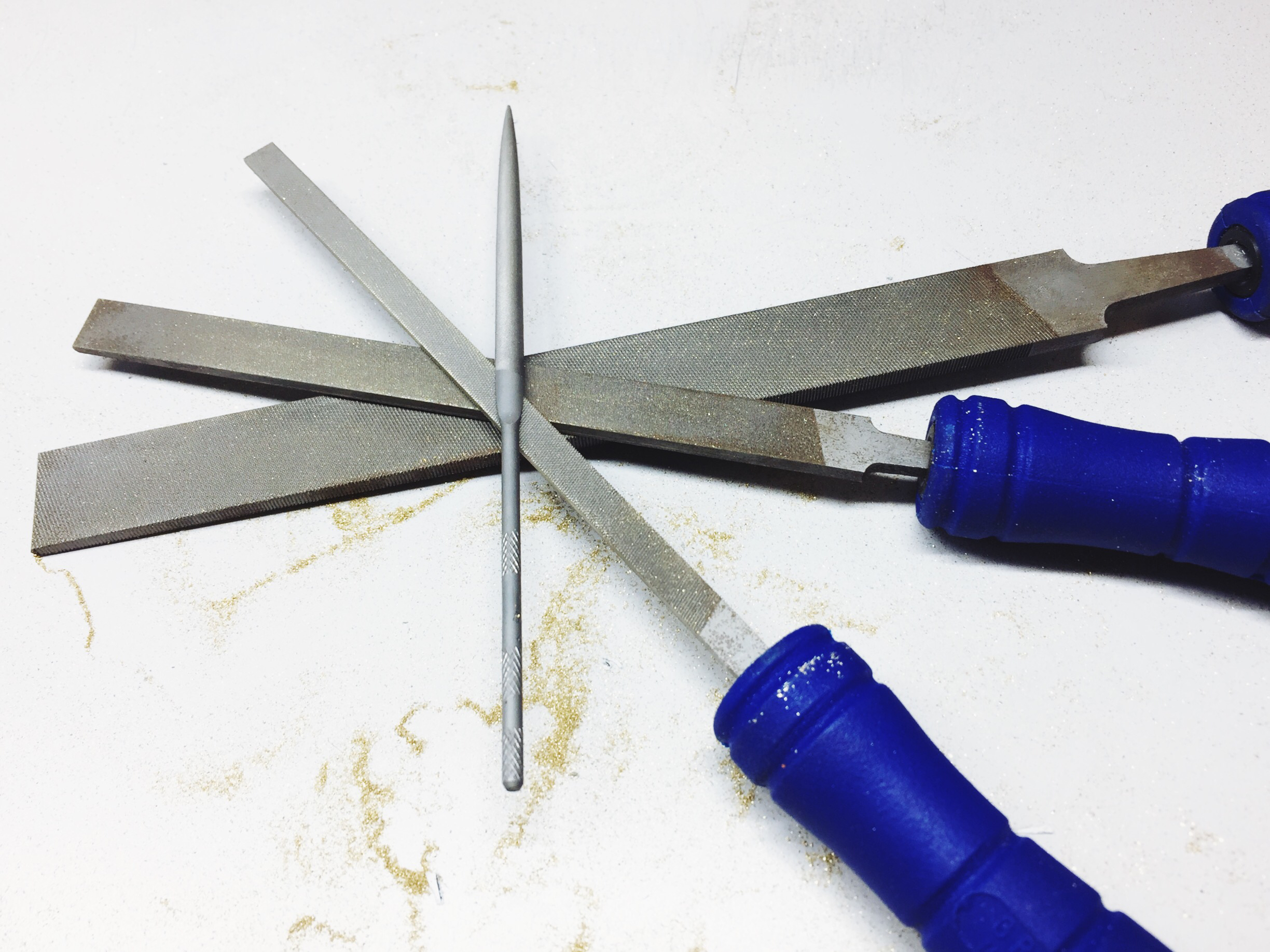

Tools: Files

When it comes to micromechanics, you live and die by your ability to file.

So far, these are our most used and most essential tools for micromechanics. The lathe might take the top spot later, but as far as hand tools go, files reign supreme.

The mark of a filing master is a smooth, square, flat surface. It seems easy, but it's devilishly hard to achieve any of those three parameters—much less all three at the same time.

We have a variety of files, all of which have different uses:

- #2 files. These are our biggest and coarsest files, used for shaping our pieces. The #2 files leaves too deep a mark on metal, so they can't be used for finishing, but their coarse teeth make them extremely efficient at removing material.

- #4 files. These are significantly finer, and are used to bring a piece almost to completion. Generally, the bigger #4 files are used after most of the shaping work is done, but before the object is within the top end of its dimensional tolerance. While the #4 leaves a very smooth surface finish, emery paper (sandpaper) is often preferred for final finishing.

- Needle files. These are thin #4 files, which come in a variety of shapes. The triangular file in the picture is used to cut V grooves, for example. These are essential for the very fine work that will come later.

So far all of our micromechanics work has involved serious filing. It's getting easier, but we're by no means finished with our training yet. The interior corners of our clock plate windows will be intentionally left unfiled for months, until we have the requisite skills.

Interior corners are in fact the great test of a watchmaker's filing ability. Sharp internal beveling is so difficult that machines can't do it—it's only possible by hand. That will come much much later.

Watchmaking student at the Lititz Watch Technicum, formerly a radio and TV newswriter in Chicago.