Intro to School Watch & Escapement Meter

Don't let all the hairspring work fool you—micromechanics is busier than ever these days!

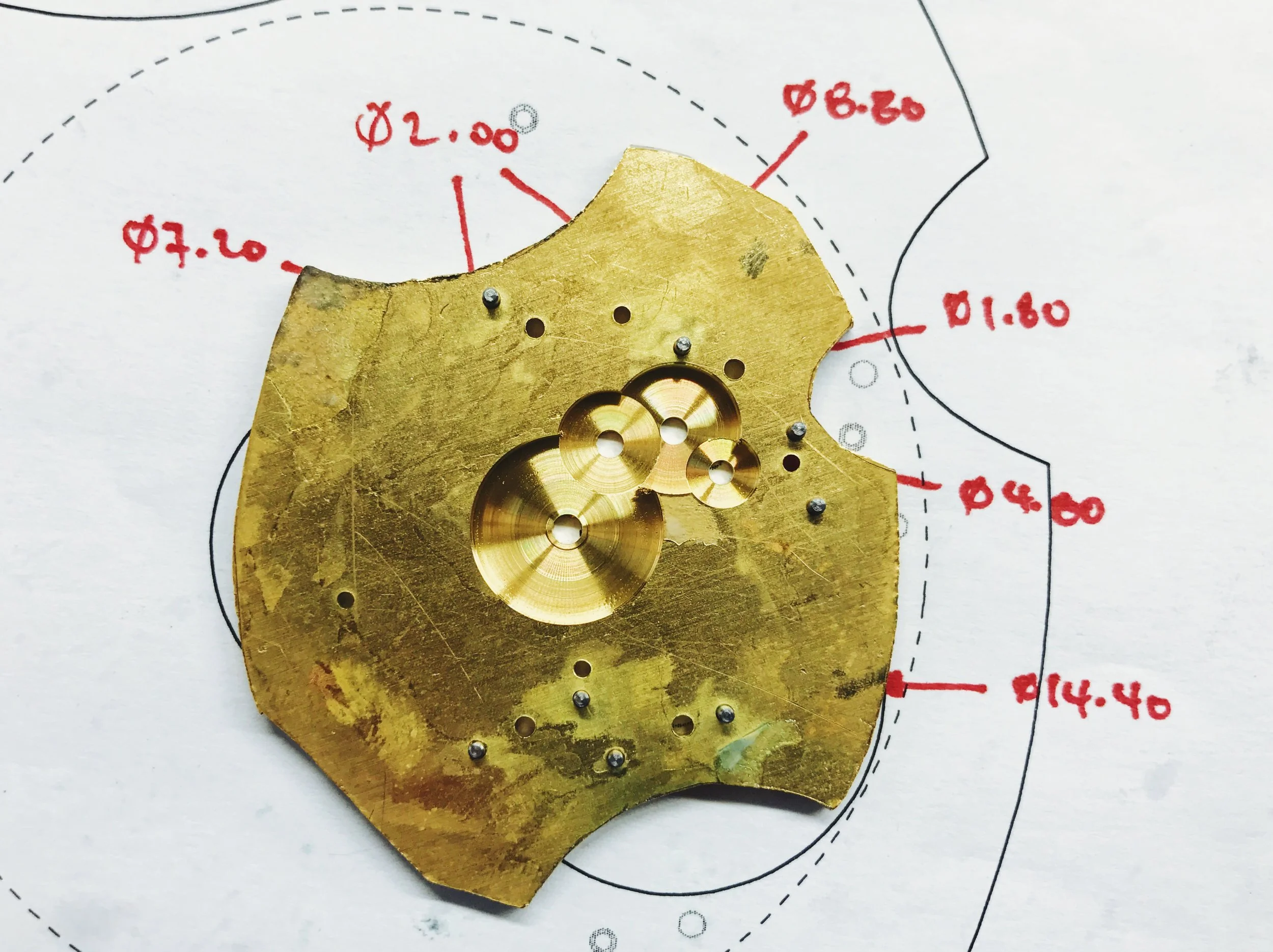

We're starting on two big new projects, which should take us through the end of the first year and into the second. They don't look like much in the photo above, but they'll be something to behold in a few months.

First up we have the school watch! We come out of our program with a maximum of three watches, but this is the one we'll be doing the most work on.

The school watch is based on the trusty ETA 6497, which we've trained on extensively. We will be forming a variety of parts, many of which will be optional/based on our skill level, but the main components will be the bridges.

We won't remake the mainplate or the wheels and pinions, for one significant reason: they require milling. We have larger toolmaker lathes for milling operations at our school, but there are only two of them for both years of students—there's just not enough time to train everyone and have them execute the projects to completion.

The first steps in forming the bridges is forming the steady pins and screw holes to secure them to the mainplate. Steady pins are the primary locators for bridges, and must fit between the bridge and plate with no play to ensure that pivots are perfectly aligned. The screws simply need to line up well enough to screw in.

The bridges are currently all one big piece of brass, and are mounted to the mainplate with the steady pins. We'll be cutting the screw recesses soon, which will prepare us for the heart of the project: cutting the jewel recesses to mount the pivots.

Next up is the escapement meter!

We use the escapement meter to precisely adjust the depthing of the pallet jewels during service. They can be hard to come by on the secondary market, and they cost upwards of a thousand dollars if you buy them new, so it'll be a great tool to make for ourselves.

https://www.instagram.com/perplxr/

This is a nearly-finished prototype of the project. The original tool is extensively milled, but we will be hand-filing "layers" of the tool instead (they have been left intentionally unblended in the above photo so you can tell them apart). This project will introduce us to gear cutting, but the geartrain is significantly simpler and shorter than the watch, so it will be possible to get us all through it in the time we have.

These two projects will take our micromechanics skills far beyond their current levels, and they'll be extremely challenging. Stay tuned!

Watchmaking student at the Lititz Watch Technicum, formerly a radio and TV newswriter in Chicago.