Micromechanics: Fasteners

What do you do if you need a part but don't want to buy it? Make it!

The school clock requires several nuts to hold it together in various ways. All six plate pillars are fastened with them, as well as the click post. We really only have to make one nut for the click, but it's easy enough to make several all at the same time.

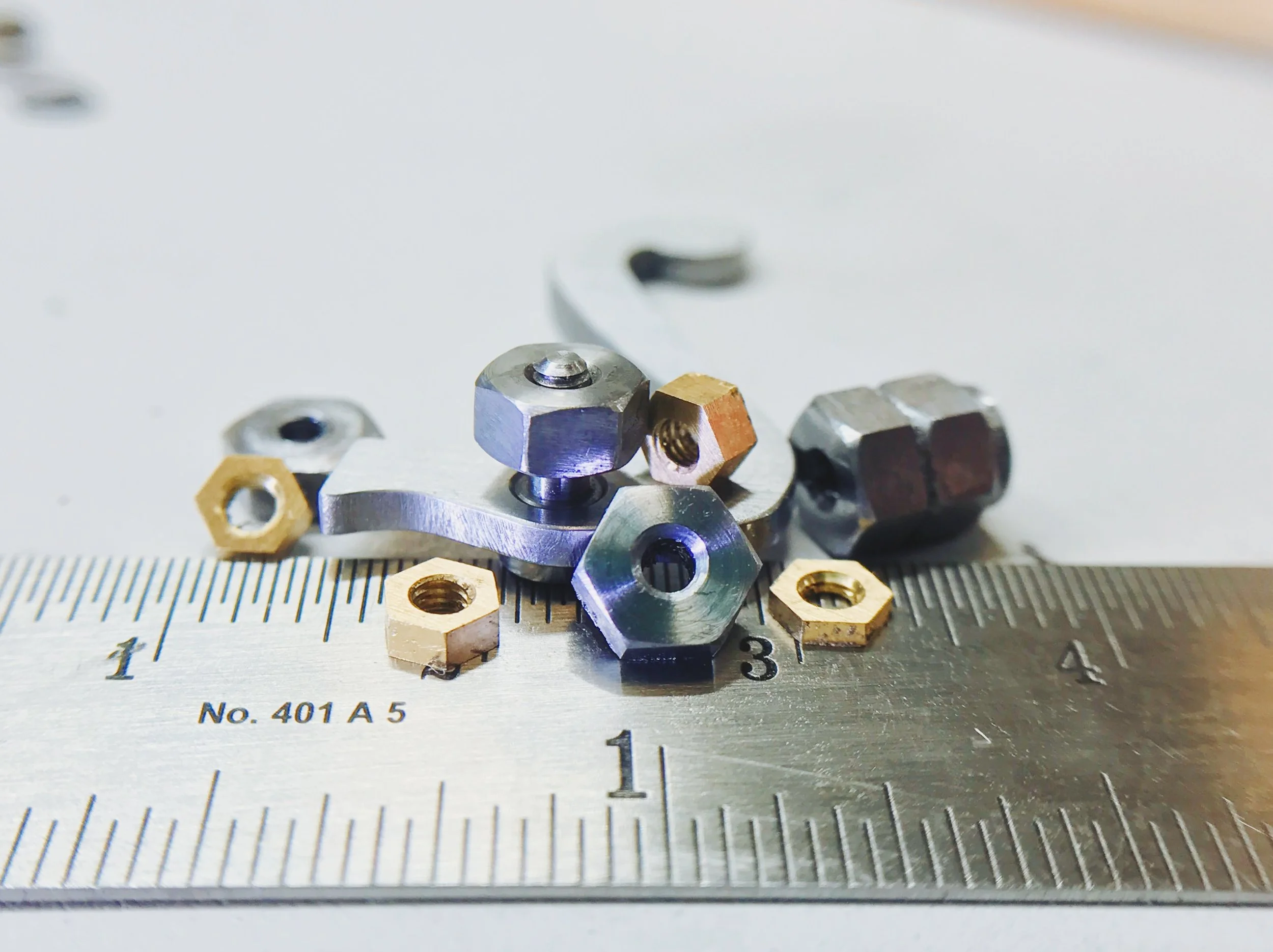

Pictured above are several test nuts I made for the click, in various degrees of finish. As with anything, they have to be finely crafted and finished to live up to watchmaker standards.

Making a nut is pretty simple, if delicate. Our lathe has indexing functions that allow us to lock the cylindrical workpiece at defined angles, to file in the correct shape (in this case, a hexagon), and then it's drilled and tapped for threads. Finally, the long nut tube is parted off into slices, beveled and lapped for surface finish.

Technically, this could all be done free-hand, but it'd be devilishly hard. The lathe allows us to keep the hole concentric to the workpiece, and holds it steady for filing. Doing it right is more a matter of patience and care than anything else.

Watchmaking student at the Lititz Watch Technicum, formerly a radio and TV newswriter in Chicago.