SAWTA Prep: Tool Dressing

It's always important to keep your tools in the best possible condition, but that's doubly true during one of our do-or-die exams.

Screwdrivers and tweezers will gradually wear out over time, especially with softer metals like brass and bronze. They both require regular dressing, especially if screwdrivers are going to be used with different calibres.

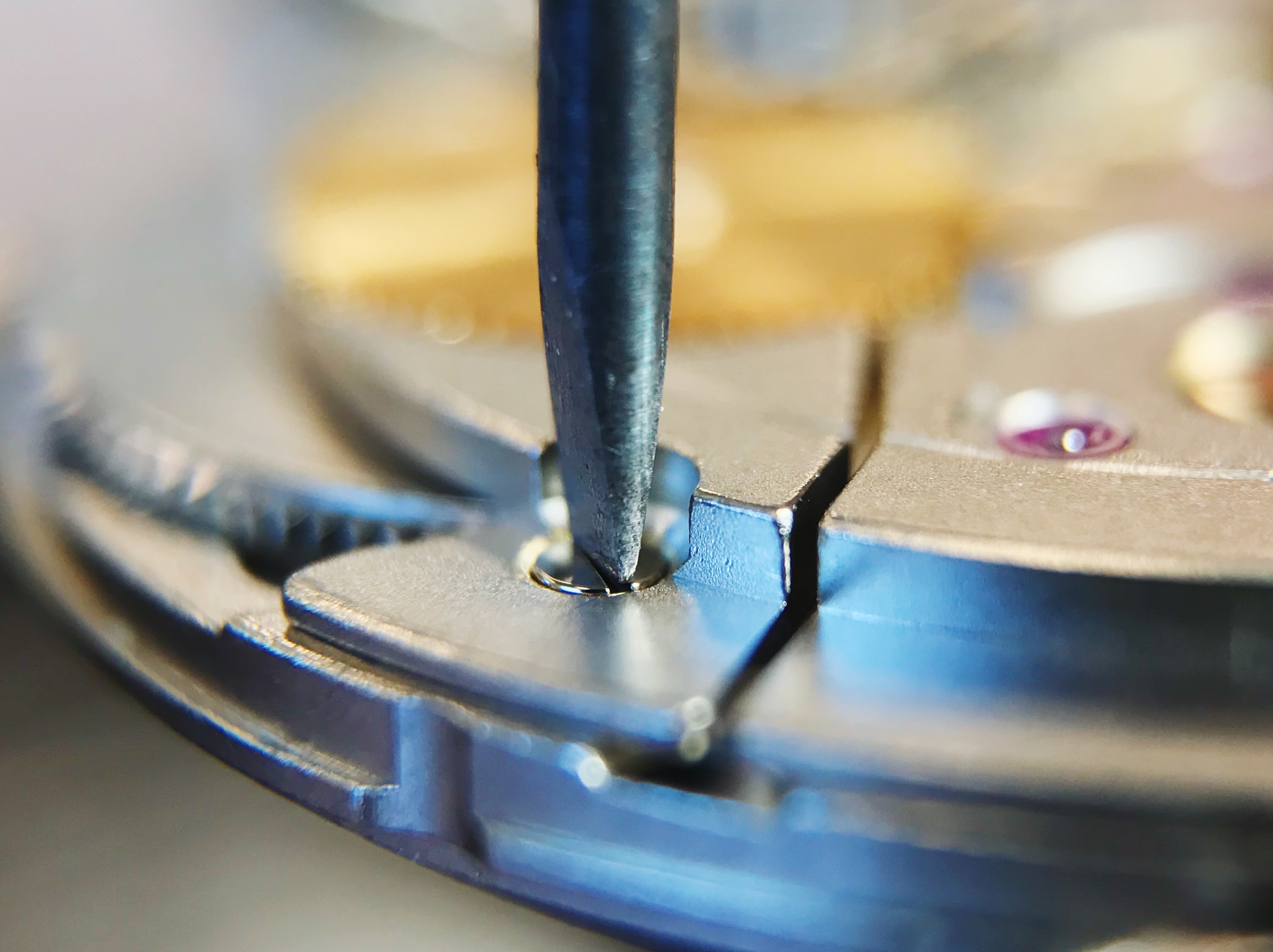

A screwdriver blade must fit perfectly into the slot, with no rotational play. A screwdriver that can rotate in the slot will put all of its torque into the slot's extremities, pushing up a burr and making the slot vaguely S-shaped. This blade is too thin (you can see the gap between the slot and the blade towards the left side, and will need to be dressed.

Screwdrivers and tweezers are both sharpened at an oilstone. The red India stone is used to shape the blade, and the white Arkansas stone deburrs it. Screwdriver tips are thickened by grinding the tip perpendicular to the stone, and thinned by grinding at the blade's native angle.

This is what the fit to the screw slot should look like: no air gap, no play. It's tricky to properly dress screwdrivers for the 2824's screws (seen above), since they have very shallow slots and a domed head. Hollow-grinding might be preferred here, but that requires a different technique.

Too-thin screwdriver blades also run the risk of slipping out of the slot and scratching the bridge. If the screwdriver is too thin, as seen here, and hits the bottom of the slot, it can be very hard to control.

Properly-sharpened blades, then, will fit into the slot not only with zero rotational play, but with a jam fit that ends above the bottom of the slot. This is where taper grinding (traditional screwdriver grinding) has an advantage over hollow-grinding. This kind of taper fit secures the blade to the slot and helps reduce unwanted slippage.

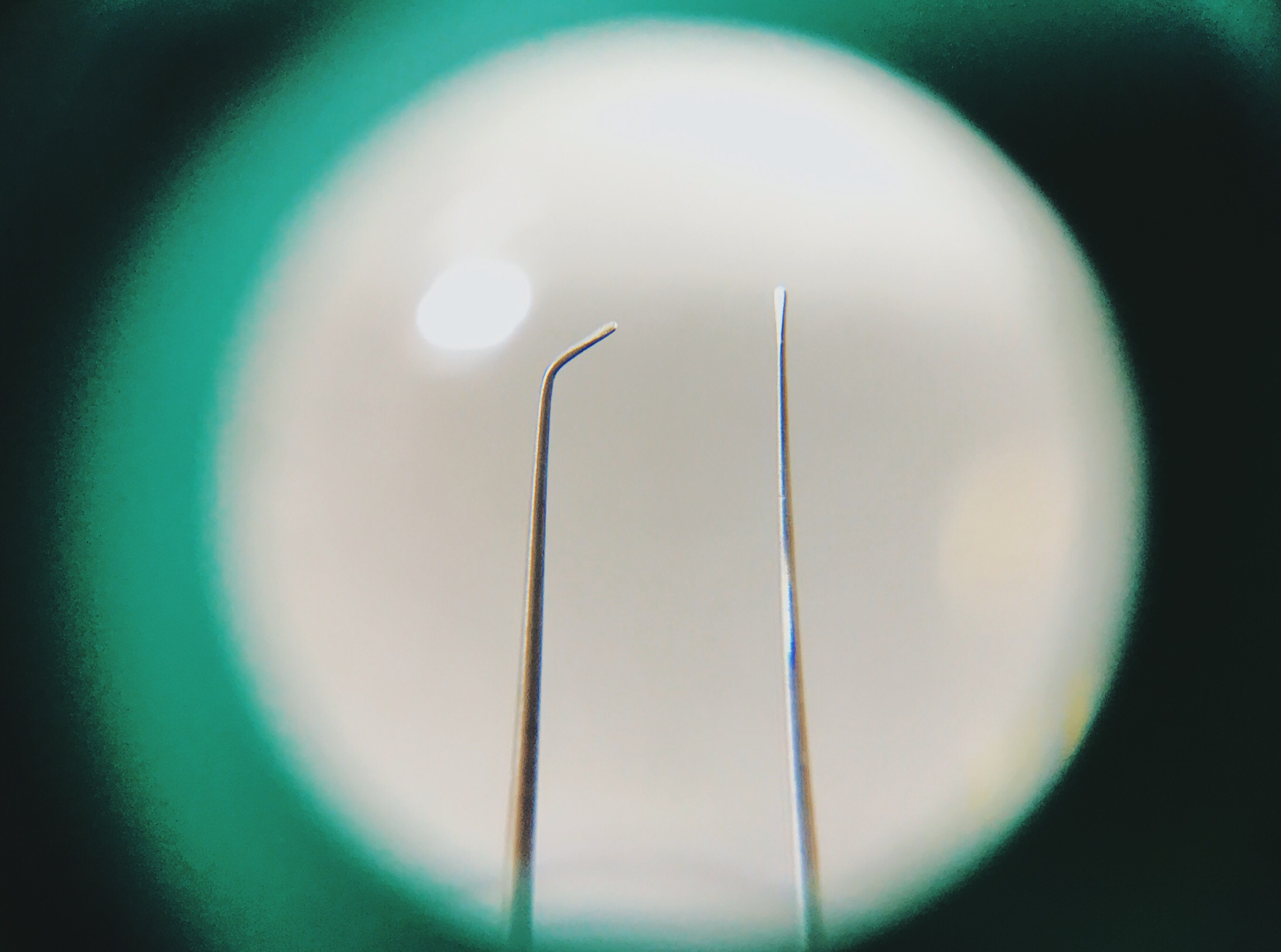

Tweezers don't generally have movement-specific requirements, but they still need attention. The tips in the photo above are worn out, rounded, scuffed and uneven. This happens in regular use, and can make it difficult to pick up small objects—or worse, shoot small parts into orbit when the tips slip.

The sharpening process for tweezers is identical: perpendicular grinding to even and blunt the tips, and grinding at an angle to sharpen them again. These tweezers will wear out more quickly than you might imagine, but soft metals like bronze are easy to sharpen. The improved meeting of the tip points makes for a much more secure grip on small and large components alike!

Watchmaking student at the Lititz Watch Technicum, formerly a radio and TV newswriter in Chicago.