Micromechanics: Lathe

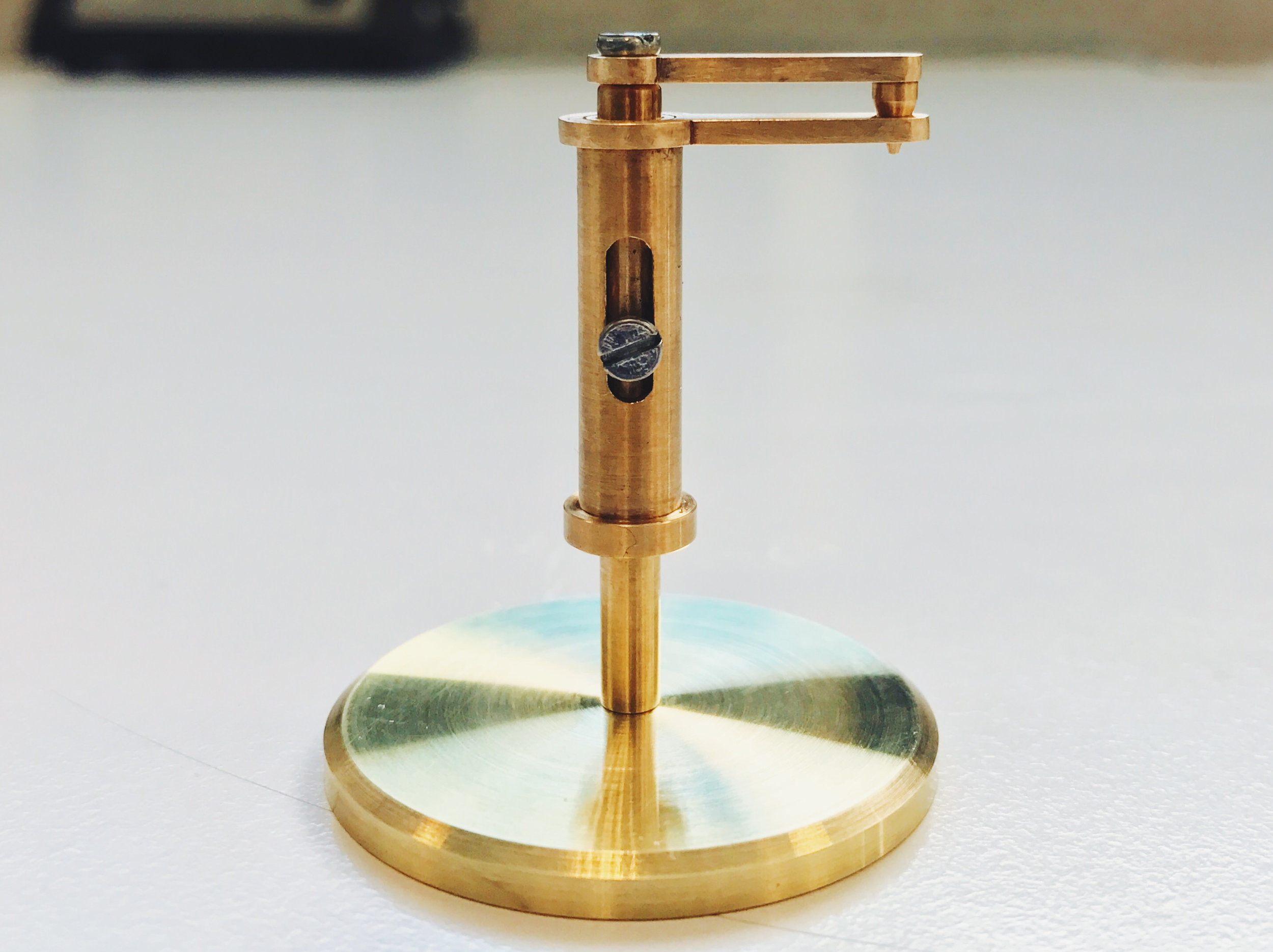

If there's one tool that we'll use for micromechanics in the professional world, it's this.

The lathe is a phenomenally important tool, and is one of the "big three" tools in machining (other than the mill and the drill press). In short, it's used to cut things that are round.

A common use for lathes in the field is to re-pivot wheels. Old non-shock-protected watches can break their balance wheel pivots easily, and other pivots can simply wear out from use (and infrequent lubrication). Pivots are steel, and are extremely small. That's not where we're starting.

As with other micromechanics projects, we're beginning with brass. Its softness makes it easier to machine, and it won't wear down our cutter as easily. Did I mention that we also have to make our own cutters?

The cutter is a piece of "high speed" steel. We received a blank, and were given instructions on how to cut it into a lathe bit using a grinding wheel. Cutter geometry is extremely complex, but I'll talk more about that later. You can see my bit here in the picture—it's not great, but it's a first attempt. It cuts.

These are watchmaker's lathes (naturally), and are very precise. They're capable of cutting and measuring as little as 0.01 mm, and sometimes even less. Tolerances for lathe-turned objects is very low, usually between 0.05 mm and 0.03 mm. That's small.

Right now we're just learning the tool and playing around with it. Our micromechanics courses from here on out will almost all involve the lathe, so get ready to hear a lot more about it!

Watchmaking student at the Lititz Watch Technicum, formerly a radio and TV newswriter in Chicago.