Micromechanics: Practial Exam

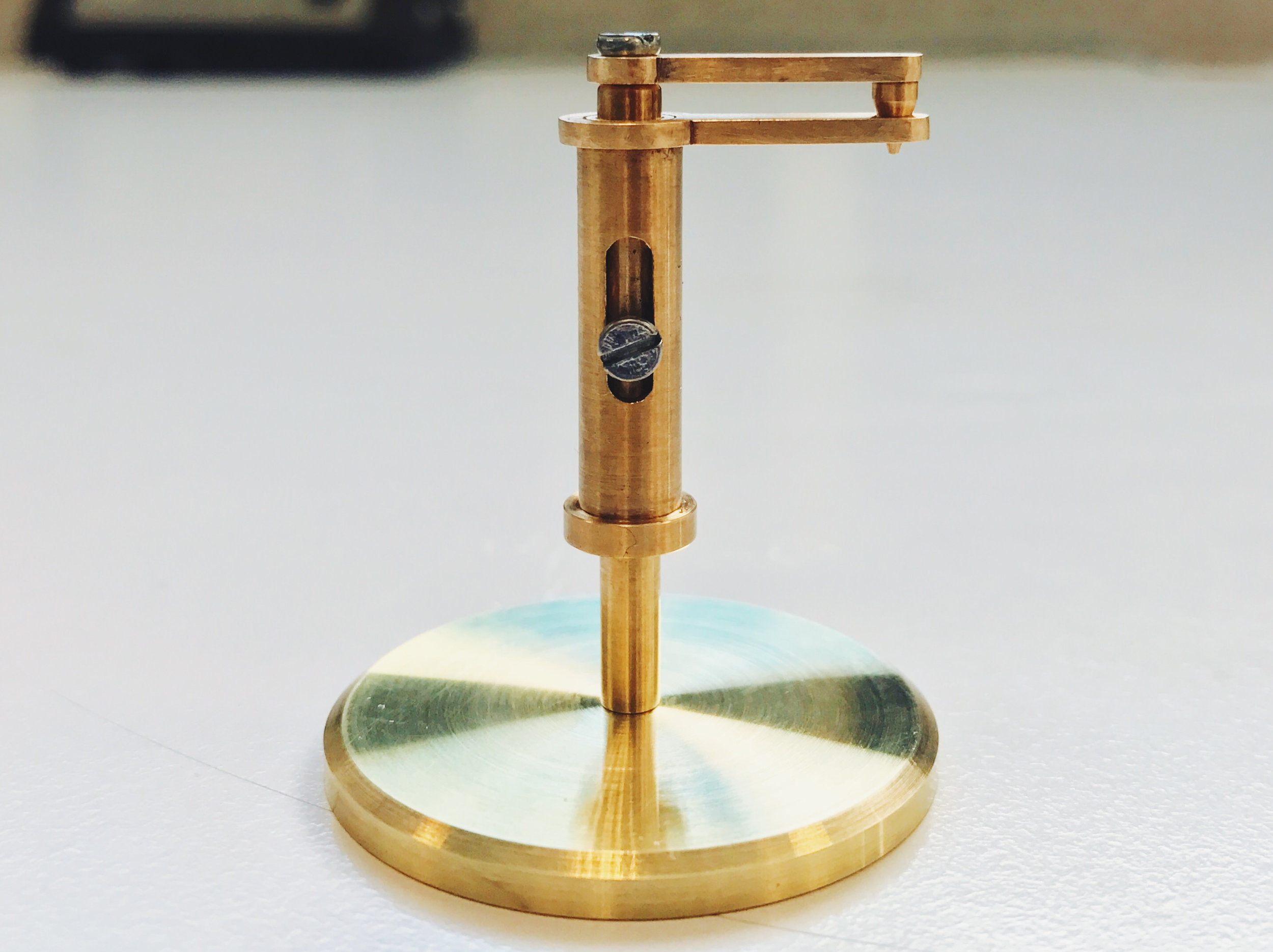

16 hours of stressful work under exam conditions, and this is the result: a 6-component rotating balance tack.

This is our second practical exam leading up to our do-or-die SAWTA 1 test, and it's a comprehensive assessment of most of our main micromechanics proficiencies so far. To wit:

- Turning: The post, sleeve, base and cone all had to be turned at the lathe. The post was challenging because it was nearly 40 mm long (that's HUGE in the watchmaking world), the sleeve had to be drilled through along two axes, and the base had to be turned down on a shellac chuck from flat stock into a cylinder. The cone and the sleeve both have friction fit elements, which require a 0.00 mm tolerance.

- Filing & Sawing: The arms not only have to be drilled to have their holes be concentric and properly aligned, but they have to be sawn and filed to precise dimensions—with impeccable surface finish! This was an area that tripped up myself and many of my classmates. The holes must align for the tool to work, which is pass/fail. Luckily, mine did. My dimensions were slightly oversized though, which is a big no-no. Dimensions left over tolerance are unacceptable because they can be easily reduced with more filing.

- Drilling: The sleeve is drilled all the way through, as well as through the side (which is filed to completion for the slot). The post is drilled at the top and through the side for threads. The arms are drilled to sit on the sleeve & post on one side, and to locate the cone on the other.

- Threading: The post is threaded into the base, at the top and in the side.

- Broaching & Reaming: One hole in each arm has to be broached to a friction fit with its associated turned component.

The dimensions and surface finish should be excellent on this project, but the most important aspect is functionality. The cone needs to precisely seat into the screw hole for a balance bridge, allowing the bridge to be held securely while the balance wheel is free to hang below it.

The above picture was taken during testing, and you can see a good number of flaws, including unfinished filing, an unscrewed base, and many many fingerprints. Those all have to be fixed before turning a project in!

Balance tacks are mostly used for older watches and pocket watches that don't have adjustments for the beat error—that is, how equally the balance wheel swings from side to side in the movement. It's a complicated adjustment that I'll explain later on. Otherwise, it works nicely to hold the balance during service, keeping the spring and sensitive pivots out of harm's way.

SAWTA 1 is coming up, and that's a big deal! We'll be practicing our micromechanics skills as much as possible during the next week to prepare.

Watchmaking student at the Lititz Watch Technicum, formerly a radio and TV newswriter in Chicago.