Intro to Micromechanics

Draw a square.

Simple, right? Now make that square perfectly square, with perfect 90° angles. Now make sure those lines are 50 mm per side, +/- 0.1 mm. That's 1/5th the diameter of a "fine" mechanical pencil lead. You'll have to sharpen it!

Done? Great. You've completed your first micromechanics project.

Watchmaking school isn't just about repairing and servicing watches. Oh no. About half of the classes in our first year are dedicated to micromechanics, which is to say making stuff out of wood and metal.

Many of the world's most highly skilled contemporary watchmakers started their careers by repairing vintage and complicated timepieces, which often require replacement parts to be made by hand, from the bare metal. Two years isn't enough time to master micromechanics, but it will give us a great start.

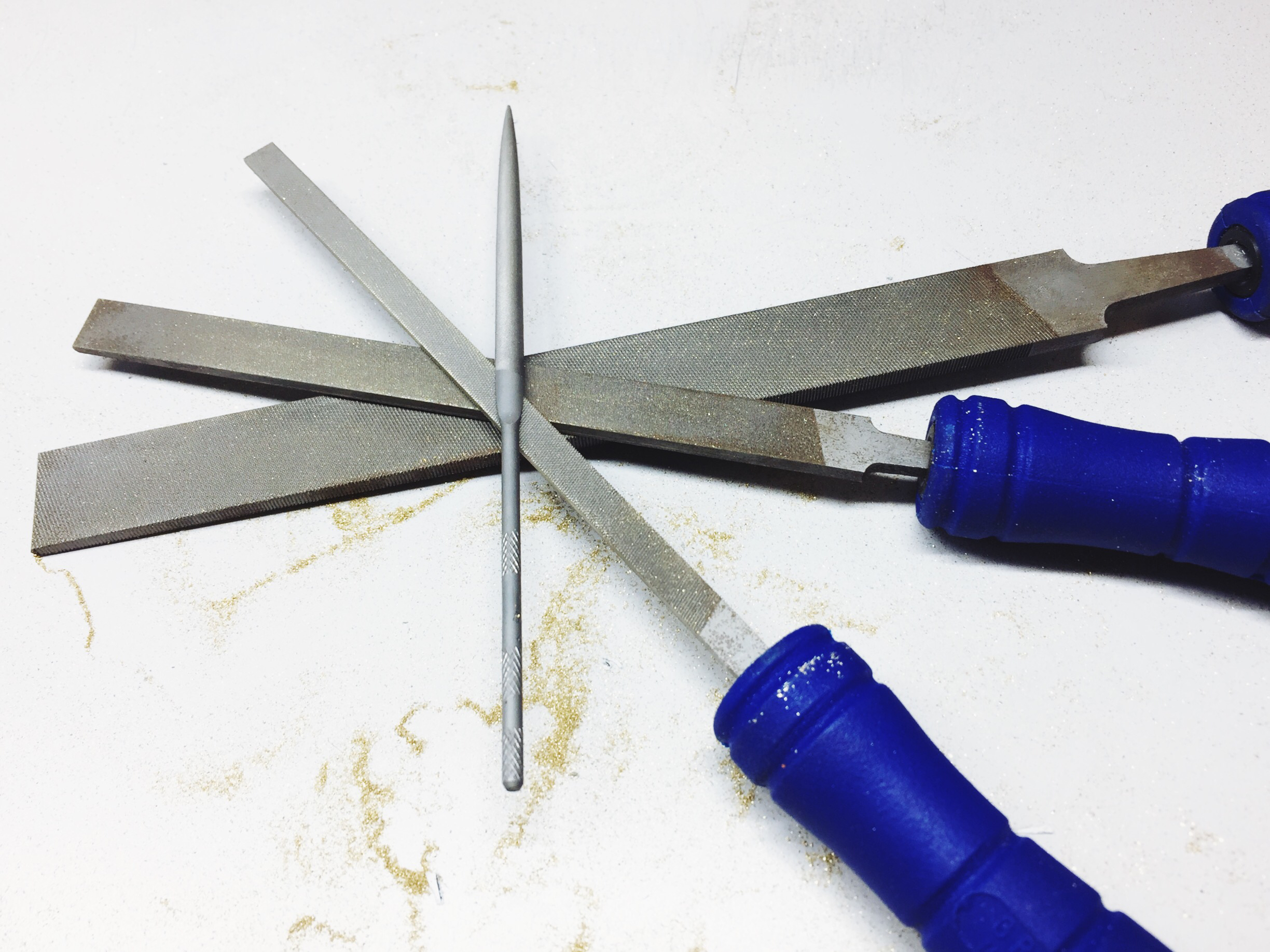

Our projects start with simple shapes to get us used to our files and saws. Later, we'll build a clock, then a watch, and it'll only get smaller and more complex from there.

I'll talk a lot more about the tools later, and the projects as we complete them. In the meantime, practice those squares!

Watchmaking student at the Lititz Watch Technicum, formerly a radio and TV newswriter in Chicago.